Ukufakwa kwepayipi le-Kingflex kwenziwa nge-NBR kanye ne-PVC

Incazelo

Ukufakwa kwepayipi le-Kingflex kuyinto yokuvikela ukushisa yepulasitiki yerabha esezingeni eliphezulu. Ine-conductivity engcono yokushisa, Iphinde ibe nokufakwa kwe-insulation okungcono kokushisa, isici sokonga amandla kanye nesici sokumelana nomswakama esingcono kakhulu kanye nokuphila isikhathi eside kwenkonzo. Imikhiqizo ejwayelekile imnyama. Ukusetshenziswa okuyinhloko amapayipi amanzi abandayo, amapayipi okuhlanganisa, amapayipi omoya kanye namapayipi amanzi ashisayo emishini yokupholisa umoya kanye nokugcinwa kwe-insulation yokushisa kwesistimu yokupholisa umoya ephakathi kanye nazo zonke izinhlobo zamapayipi abandayo/ashisayo aphakathi nendawo.

Ishidi Ledatha Lobuchwepheshe

| Idatha Yobuchwepheshe ye-Kingflex | |||

| Impahla | Iyunithi | Inani | Indlela Yokuhlola |

| Ibanga lokushisa | °C | (-50 - 110) | GB/T 17794-1999 |

| Ububanzi bobuningi | Amakhilogremu/m3 | 45-65Kg/m3 | I-ASTM D1667 |

| Ukuvuleka komoya wamanzi | kg/(mspa) | ≤0.91×10 ﹣¹³ | I-DIN 52 615 BS 4370 Ingxenye 2 1973 |

| μ | - | ≥10000 | |

| Ukuqhuba Okushisayo | W/(mk) | ≤0.030 (-20°C) | I-ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Isilinganiso Somlilo | - | Isigaba 0 kanye nesigaba 1 | BS 476 Ingxenye 6 ingxenye 7 |

| Inkomba Yokusabalala Komlilo kanye Nokuthuthukiswa Komusi |

| 25/50 | I-ASTM E 84 |

| Inkomba ye-Oxygen |

| ≥36 | I-GB/T 2406, ISO4589 |

| Ukumuncwa Kwamanzi,%ngoMqulu | % | 20% | I-ASTM C 209 |

| Ukuqina Kobukhulu |

| ≤5 | I-ASTM C534 |

| Ukumelana nesikhunta | - | Kuhle | I-ASTM 21 |

| Ukumelana ne-ozone | Kuhle | I-GB/T 7762-1987 | |

| Ukumelana ne-UV nesimo sezulu | Kuhle | I-ASTM G23 | |

Izinzuzo zomkhiqizo

1. Isakhiwo Seseli Elivaliwe

2. Ukushisa Okuphansi Komoya Oshisayo

3. Ukushisa okuphansi, Ukunciphisa okuphumelelayo kokulahlekelwa ukushisa

4. Ingashi, ayizwakali, iguquguquka, iyanwebeka

5. Isivikelo, ukuvimbela ukungqubuzana

6. Kulula, kuyashelela, kuhle futhi kulula ukufaka

7. Kuphephile ngokwemvelo

8. Isicelo: umoya opholile, uhlelo lwamapayipi, igumbi lesitudiyo. isakhiwo seworkshop, ukwakhiwa, imishini njll.

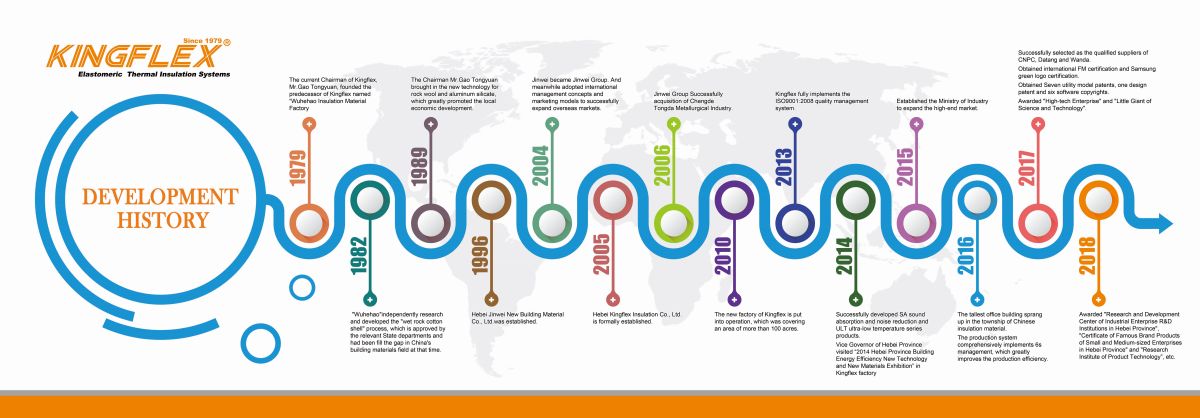

Inkampani Yethu

Umbukiso wenkampani

Isitifiketi

Izigaba zomkhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp