Ipayipi le-foam yerabha ye-Kingflex isebenzisa i-NBR (irabha ye-nitrile-butadiene) njengezinto eziyinhloko zokusetshenziswa

Ishidi Ledatha Lobuchwepheshe

| Idatha Yobuchwepheshe ye-Kingflex | |||

| Impahla | Iyunithi | Inani | Indlela Yokuhlola |

| Ibanga lokushisa | °C | (-50 - 110) | GB/T 17794-1999 |

| Ububanzi bobuningi | Amakhilogremu/m3 | 45-65Kg/m3 | I-ASTM D1667 |

| Ukuvuleka komoya wamanzi | kg/(mspa) | ≤0.91×10 ﹣¹³ | I-DIN 52 615 BS 4370 Ingxenye 2 1973 |

| μ | - | ≥10000 |

|

| Ukuqhuba Okushisayo | W/(mk) | ≤0.030 (-20°C) | I-ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Isilinganiso Somlilo | - | Isigaba 0 kanye nesigaba 1 | BS 476 Ingxenye 6 ingxenye 7 |

| Inkomba Yokusabalala Komlilo kanye Nokuthuthukiswa Komusi |

| 25/50 | I-ASTM E 84 |

| Inkomba ye-Oxygen |

| ≥36 | I-GB/T 2406, ISO4589 |

| Ukumuncwa Kwamanzi,%ngoMqulu | % | 20% | I-ASTM C 209 |

| Ukuqina Kobukhulu |

| ≤5 | I-ASTM C534 |

| Ukumelana nesikhunta | - | Kuhle | I-ASTM 21 |

| Ukumelana ne-ozone | Kuhle | I-GB/T 7762-1987 | |

| Ukumelana ne-UV nesimo sezulu | Kuhle | I-ASTM G23 | |

Isicelo

Ipayipi le-foam yerabha ye-Kingflex lingasetshenziswa ukuvikela amapayipi nemishini. Ngenxa yokushisa okuphansi kwebhodi lokuvikela irabha nepulasitiki, akulula ukuhambisa amandla, ngakho-ke lingasetshenziswa kokubili ukuvikela ukushisa kanye nokuvikela ukubanda.

Ipayipi le-foam yerabha ye-Kingflex lingasetshenziswa ukuvikela amapayipi nemishini. Izinto zepayipi lokufaka irabha nepulasitiki zithambile futhi ziyanwebeka, ezingavikela futhi zimunce ukushaqeka. Ipayipi lokufaka irabha nepulasitiki lingavimbeli amanzi, livikele umswakama futhi livikele ukugqwala.

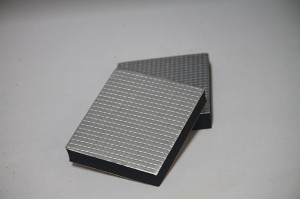

Ipayipi le-foam le-Kingflex le-raber lingadlala indima yokuhlobisa kumapayipi nemishini. Ukubukeka kwepayipi lokuvikela i-raber-plastic kubushelelezi futhi kuyisicaba, futhi ukubukeka kwayo konke kuhle.

Ipayipi le-foam yerabha ye-Kingflex linokuqina okuhle kakhulu futhi lingadlala indima enhle ekuvimbeleni umlilo.

Ipayipi le-foam yerabha ye-Kingflex liyaguquguquka, ngakho-ke kulula ukulifaka uma kudingeka ligotshwe.

Inkampani Yethu

Umbukiso wenkampani

Isitifiketi

Izigaba zomkhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp